Diamond Grading – The AGSL Way (part five)

*The following article provides an overview of the American Gem Society Laboratories approach to cut grading of princess diamonds, and was written in collaboration with the AGSL. Special thanks to Peter Yantzer in providing information and insight, Rachel Stark for providing graphics, and to Alethea Inns and Jason Quick for their encouragement and support.

This article will focus on the particular issues involved in light performance grading specific to princess cut diamonds. We will delve more deeply into the underpinnings of the AGS light performance based cut grading system and the round brilliant in a future article. For a look at the peer reviewed science behind the AGS system that was years in the making you can refer to the landmark study which appeared in 2007 in the journal Optical Engineering, entitled “Evaluation of Brilliance, Fire, and Scintillation in Round Brilliant Gemstones.” Foundational work on the project was published in Optics and Photonics News in April of 2003 entitled “The Optical Design of Gemstones.”

Development of the Princess Cut

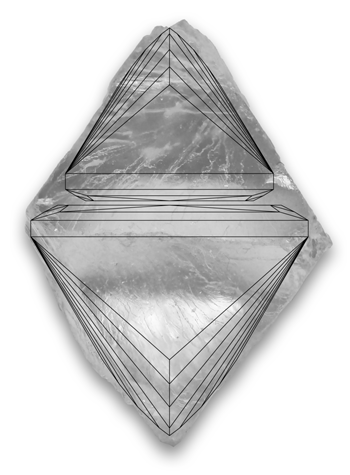

The diamond shape generically referred to as the “Princess Cut” is a square or rectangular modified brilliant cut that encompasses a variety of similar faceting patterns. It is a relatively recent addition to the menu of diamond shapes, having been first introduced in the 1960’s. The precursor to the modern princess is widely considered to be the “Barion” cut, although it was really more like a radiant featuring clipped corners. The Barion was invented by Basil Watermeyer and got its name from a combination of his first name and that of his wife Marion.

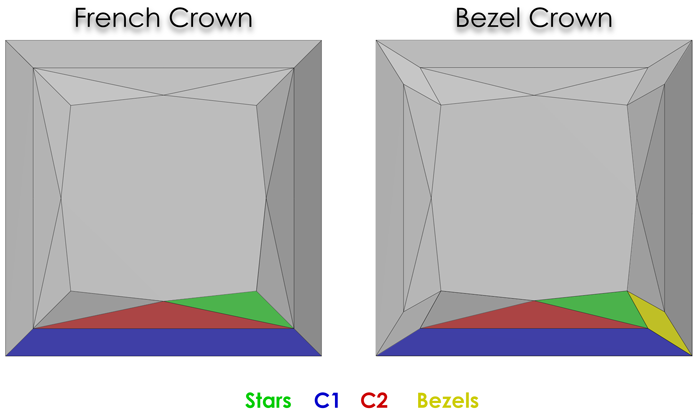

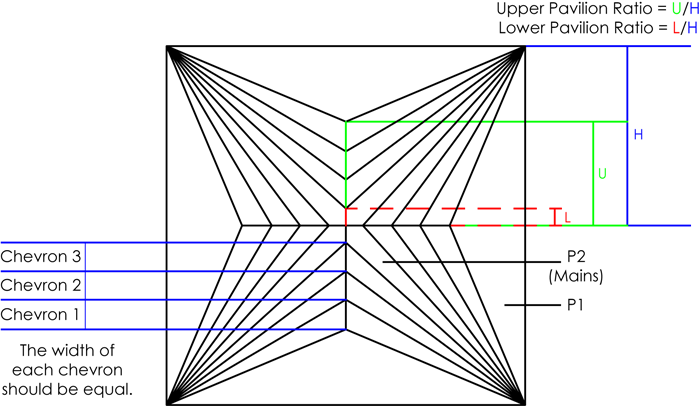

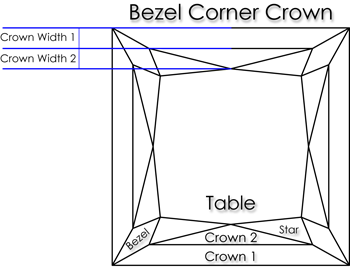

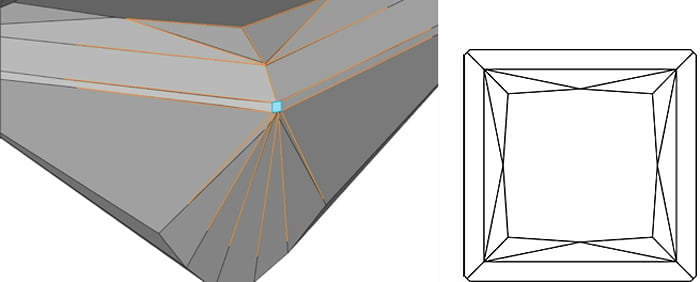

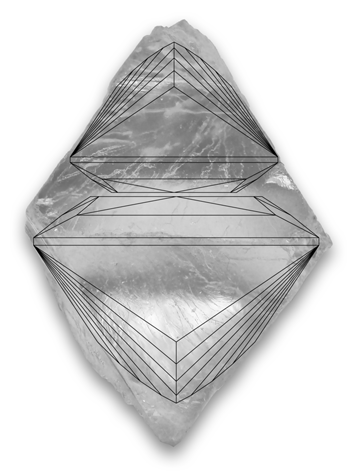

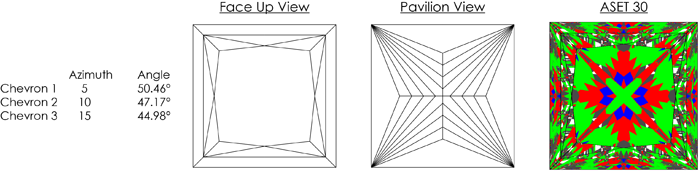

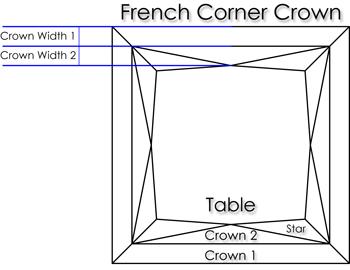

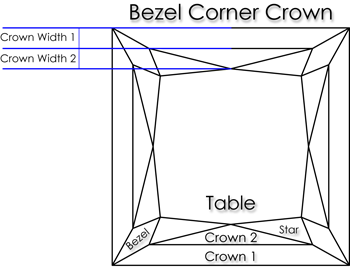

The crowns of the modern princess cut are designed in two basic styles; Bezel corners with a small diamond shaped facet from the table corner to the stone corner, and French corners where the star facets point to the stone corners and usually extend about 50% of the distance from the table corner to the stone corners. (Figure 1)

Figure 1 (courtesy of AGSL)

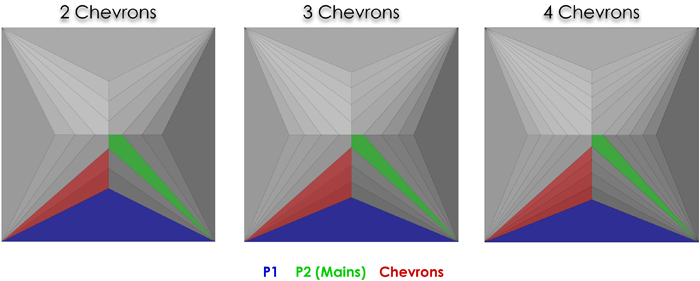

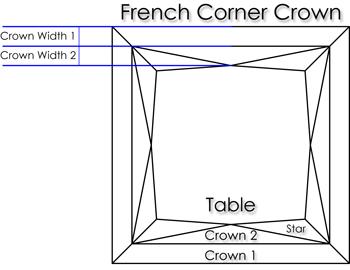

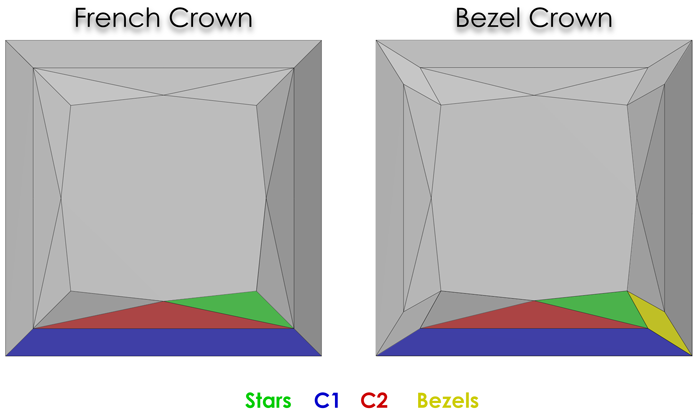

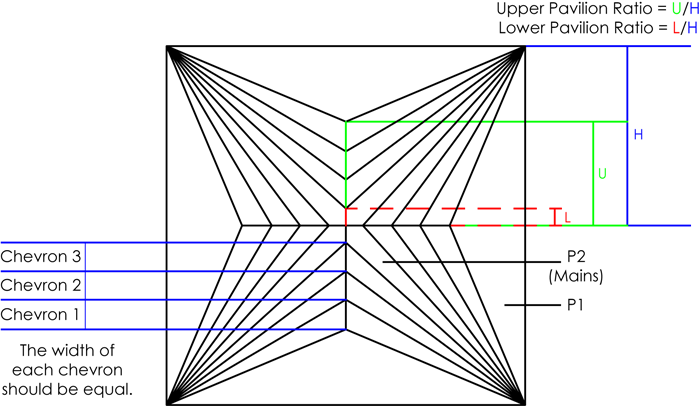

The princess cut has two sets of main crown facets and two sets of main pavilion facets (as opposed to one of each for rounds). Variations of the princess usually include facet arrangements consisting of pavilion configurations of 2, 3, or 4 tiers of chevron facets (Figure 2). Larger stones are sometimes cut with even more tiers of chevrons.

Figure 2 (courtesy of AGSL)

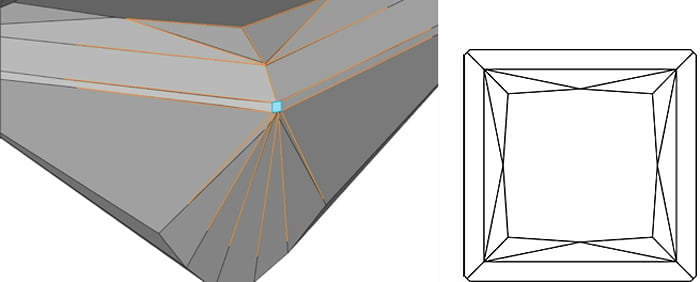

The girdle corners are sometimes cut with very small facets- a technique known as “chamfering”- in order to make them less vulnerable to chipping. (See Figure 11)

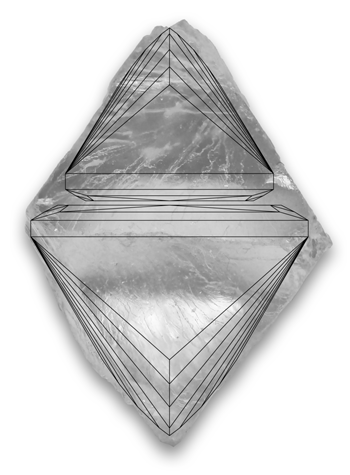

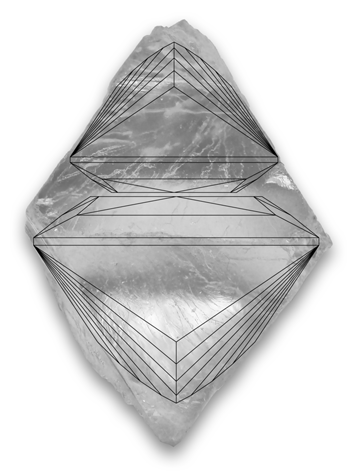

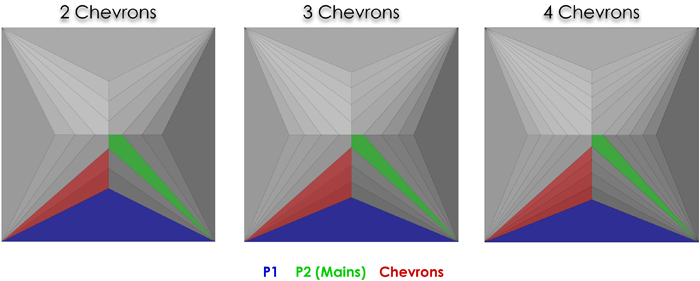

Development of the princess cut created a fusion between the sparkle of the round brilliant and the rectilinear outline of square or rectangular step cuts such as the emerald cut or Asscher. And it provided a means for diamond cutters to extract more finished diamond weight from an octahedral crystal, a common form of gem diamond. Typically the crystal is sawn so that two diamonds can be made – one larger and one smaller. Higher yields mean lower per carat costs resulting in lower price point options for the consumer. By virtue of these advantages, the princess cut has quickly become the second leading seller next to the classic round brilliant.

Left: Figure 3 – Commercial Princess – cut for yield • Right: Figure 4 – Ideal Princess – cut for beauty

(images courtesy of AGSL)

Background on Grading

At the time the princess cut was introduced to the market diamond grading was limited to basic weight and measurements, and assessment of color and clarity. Analysis of the cut quality of the diamond involved only an assessment of the level of polish and evaluation of “meet point” symmetry – a judgment of how uniformly the facets meet the other contiguous facets. Unfortunately, there was no assessment of overall cut quality and light performance of princess cuts for many decades. There was consequently little incentive for cutters to maximize the beauty of the princess cut in terms of fire and brilliance, but rather a strong economic incentive to derive maximum weight from the rough (Figure 3). As a result the market filled up with princess cuts that while attractive, lacked the full light performance possible for the popular new shape.

Cut quality analysis of princess cut diamonds finally came about due to the research of the American Gem Society Laboratories (AGSL) and the launch of their light performance based cut grading system in May 2005. It was first released for round brilliant cuts and later expanded for the greater complexity of fancy shapes. The princess cut was the first of several shapes to be subsequently added to the system, and was released in June of 2005. The AGSL initiative involved a team of gemologists and top scientists in the fields of optics, physics and mathematics. The first scientifically rigorous, peer reviewed cut grading system was thus born, finally providing incentive to cutters to spend the extra time and sacrifice the extra rough necessary to produce top quality princess cuts (Figure 4), with a reliable certificate to attest to their overall cut quality.

GIA ultimately released their own overall cut grade system in January 2006, but only for round brilliant diamonds. To this day GIA does not provide information on their princess cut reports that would enable a consumer to understand critical light performance aspects of their diamond. Because of the dominance of GIA, owing to their global reputation as the world’s most recognized authority on diamonds, most cutters continue to seek maximum yield and have not changed their basic production strategy. While many cutters are trying to cut princess that will achieve GIA grades of Excellent Polish and Symmetry, the proportioning that is fundamental to light performance continues to be geared for weight retention leaving the market awash in princess cuts that fall well short of their full potential for beauty. Without a widely available tool for consumers to easily understand the overall cut quality of the princess they are considering, there is little reason to believe the situation will change any time soon. Still, some astute cutters do see a growing demand among an ever more educated consumer market for diamonds of the finest cut quality. And those with the skills to do so have begun producing AGS Ideal princess cut diamonds, but quantities are very limited.

AGSL Light Performance Cut Grading

The American Gem Society was founded with a dedication to the highest standards of ethics, education, and consumer protection in the diamond industry. The AGS leadership recognized a need for cut quality analysis that the GIA was not addressing, and ultimately a decision was made to establish their own laboratory. The AGSL was born in April of 1996.

In addition to conducting comprehensive testing on diamonds to separate synthetics and treated stones, providing weights and measurements and color and clarity grading, the laboratory also offered cut grading on standard round brilliant cut diamonds. The AGS Ideal Cut or Triple Zero quickly became the gold standard and the market embraced the laboratory as the leading authority on diamond cut quality.

At that time, cut grading was still proportion based and 2 dimensional in nature. The team at AGSL led by Peter Yantzer recognized that cut grading could get much more sophisticated and precise, as optical instrumentation and computer processing was rapidly advancing. In 2000 the AGS decided to go “all in” on diamond cut grading and committed considerable resources to convene a team of top experts for the purpose of making a quantum leap in the science of diamond light performance analysis. After several arduous years of research and development utilizing sophisticated light ray tracing technologies and developing scientifically sound methodologies for analyzing the various components of diamond beauty, that breakthrough was achieved and in 2005 a new day dawned in the diamond industry with the launch of AGSL Light Performance grading.

The AGS Cut grading system today analyzes eleven separate aspects of diamond performance and craftsmanship including light performance, proportions, and finish components. Light performance aspects are brightness, leakage, dispersion and contrast. Proportion factors are girdle, durability, weight ratio, culet, and tilt. Finish aspects are polish and symmetry. The foundation of the light performance system is the ASET- Angular Spectrum Evaluation Tool – which reveals light return, light leakage and contrast and can be accurately modeled by the AGS ray tracing software engine. This tool and methodology makes it possible to evaluate all the key aspects of light performance and to create light maps to illustrate them. And the brilliance of this approach is that it can be applied to any diamond shape. AGSL now performs cut grading on ovals, emerald cuts and various proprietary cuts, in addition to round and princess.

The light performance and proportion analysis is all done by computer after the diamond is measured by one of several highly accurate non-contact measuring devices on the market today. The device measures the sizes, angles and direction of every facet of the diamond and creates a three dimensional model of the diamond. This model is then analyzed by the ray tracing engine by beaming 40,000 virtual light rays into the diamond and performing millions of calculations recording the light output of every facet. The diamond’s finish (polish and symmetry) are assessed by trained graders.

ASET Images – Computer Generated Maps and Actual Photos

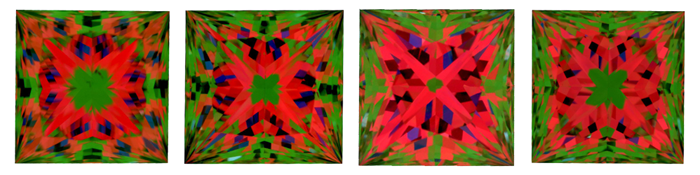

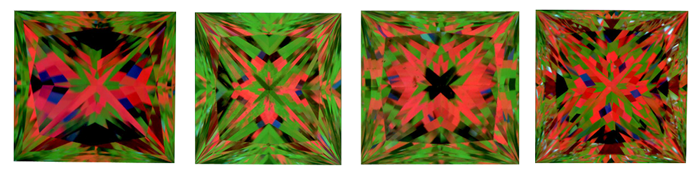

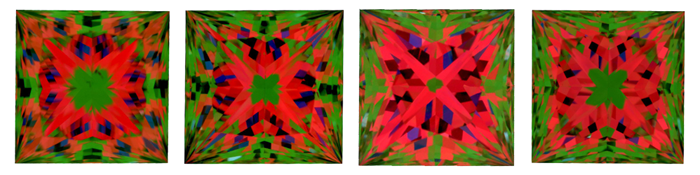

The ASET light maps generated by the ray tracing engine provide a graphical view of how the diamond is handling light from a cutting perspective. Different shapes and faceting arrangements give rise to distinctive ASET signatures. Princess cuts have a broad range of signatures due to the varied facet arrangements used in their design and execution. ASET maps of Ideal princess cuts will show a balanced mix of red and green (outstanding light return from a broad range of the angular spectrum), and only a small amount light leakage. The sample images in figures 5 and 6 are actual photographs illustrating some of the different patterns seen through an ASET viewer.

Figure 5: AGS Ideal Princess ASET samples (actual photos) Photos by Whiteflash

Figure 6:Princess ASET Samples with deficits in light performance (actual photos) Photos by Whiteflash

ASET maps generated by the AGS grading software are accurate, consistent and repeatable. They are the result of precise mathematical calculations done by the ray tracing software within the theoretical confines of the system-specific viewing hemisphere. ASET photographs taken through a viewer are subject to a variety of variables. Therefore, you may often see variances between an ASET photo and a software generated ASET map.

The Princess Cut – Complicating the Grading Puzzle

Because of the inherent symmetry and uniformity of the round brilliant shape with its 57 facets and one set of main crown and pavilion facets, it is considerably less complex and therefore relatively easier to evaluate than other fancy shapes. The princess cut by contrast has two main crown and two main pavilion facets each of which can be angled differently. It can also have different length to width ratios ranging from square to rectangular.

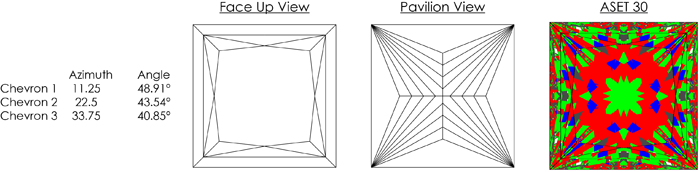

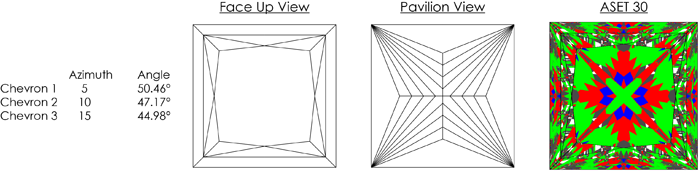

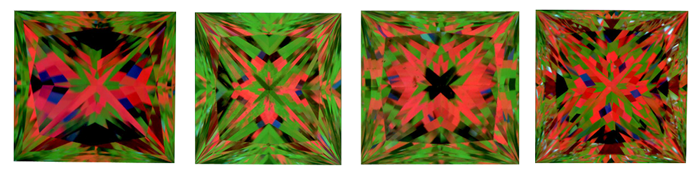

In addition, the princess cut can have a variable number of facets deriving from a 2,3 or 4 chevron configuration on the pavilion, and bezel facets or straight “French Corners” directed at the points of the crown. (*chevron arrangements in excess of 4 are also seen, particularly in larger diamond sizes). Light performance is most influenced by the cutting of the pavilion. While the two sets of pavilion mains form the basis of the princess cut, the angles and azimuths of the tiers of chevron facets on the pavilion can “make or break” its light performance – so much so that it is impossible to glean any light performance information about the princess cut knowing only the angles and azimuths of the two sets of pavilion mains. The two software generated ASET maps in Figure 7 illustrate dramatic differences in ASET signatures by altering only the chevrons. This also demonstrates why a table-based cut grading system (such as the GIA system for rounds) can never be accurate for predicting light performance for princess cuts.

Figure 7: (Graphics and ASET Maps Courtesy of AGSL)

Relatively few cutters have mastered the ability to cut princess to the demanding standards required to get an AGS Ideal cut grade. While it is not quite rocket science (despite the fact that the lead scientist on the AGSL team builds space telescopes), most cutters have not felt compelled to learn it, and so most princess cuts are manufactured in the same way they have been since the cut was first designed. They are cut primarily for weight retention and secondarily to get desirable grades on polish and symmetry from GIA in order to help market the finished diamond. AGS Ideals on the other hand are cut first for beauty and light performance. Weight is sacrificed in this tradeoff. From 12 to 20% more rough is cut away depending on the crystal (Figure 4), and much more time and skill is required on the part of the cutter.

Nomenclature and Guidance

In order to help those that do desire to learn the system, AGS consults with cutters to help with the process. The lab provides information on their website for understanding the key parameters that must be considered in the cutting process. First there are naming conventions to define the geometry, parameters and assumptions involved.

The Cutting Chart Guidelines for Princess graphically display the framework. There are separate charts for 2,3 and 4 Chevron arrangements. Each chart is specific for a given table size (in 5% increments) and contains a grid with color coded grade possibilities for combinations of pairs of pavilion and crown facets. It is important to understand that these are not grading charts, but rather provide guidance to cutters as to the potential light performance grades of various sets of parameters. An excel spreadsheet is also provided titled AGS 0 Princess Cutting Instructions.

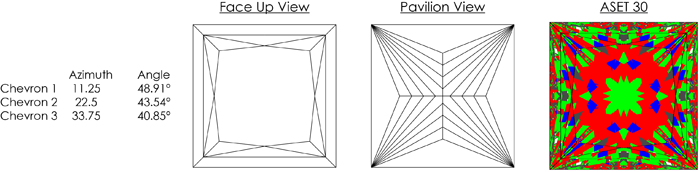

Figure 8: (courtesy of AGSL)

Figure 9: (courtesy of AGSL)

To read the charts it is necessary to understand the abbreviations for the various facets as illustrated and identified in Figures 8 and 9. The large pavilion facet that runs from corner to corner along the girdle is P1 (also known as the pavilion girdle break). The main pavilion facets that run from the corners all the way to the culet is P2.

Tiers of Chevron facets are located between P1 and P2 and extend out to the points. They are designated Chevron 2,3,4, in order from P1 to P2. As stated earlier, the princess cut can have varying numbers of chevrons.

The main crown facet is C1 and runs from corner to corner along the girdle (also know as the crown girdle break). C2 is the triangular facet above C1 that goes to the table. The crown can be cut with either star facets (French corners) or bezel facets.

There are certain assumptions indicated by the charts which are important to understand and are also found on the documents provided (and illustrated in Figures 8 an 9). First, the crown facets are modeled equal in width, as are the widths of the chevron facets. Second, the P2 facet width is defined by a ratio labeled “Lower Pavilion Ratio”. The total width of the P2 and all chevron facets is defined by a ratio labeled “Upper Pavilion Ratio”. The Upper Pavilion Ratio is usually about 5 to 10% less than the table diameter percentage (something cutters worked out through trial and error over time) and the Lower Pavilion Ratio is approximately 10%. Both of these ratios are critical in making high performing princess cuts. The star facet is assumed to have an azimuth of 6º. Cutters can deviate from these assumptions but if they go too far, the stone may suffer dramatic light performance deficits and fail to make the grade being targeted.

The more chevrons in the arrangement, the more parameters involved in the light performance calculations, and the more room for deviations that could result in grading deductions. This is why you tend to see more 2 and 3 chevron arrangements with AGS 0 reports. In addition to the increased chances of light performance deductions, achieving Ideal symmetry is more challenging the more chevrons you have, due to how long and thin they are. Achieving Ideal polish likewise is made more difficult with the increase in the number of facets and facet angles. Because of differences in the carbon lattice of diamond in certain directions, some angles are more difficult to polish than others. With a higher complexity of angles to deal with, the chances of encountering a difficult polish direction increase significantly.

While the number of chevrons is optional and many different arrangements can achieve the Ideal grade, it does vary the “flavor” of the diamond. Putting more facets on a given surface area will cause those facets to be smaller. Smaller facets result in smaller reflections, producing more twinkle than flash. This is sometimes referred to as a “crushed ice” effect. A customer who prefers the look of broader flash and larger sparkles will likely prefer arrangements with fewer chevrons. The visual impact of the chevron pattern is also relative to the size of the diamond.

Designing the Standard for Princess Light Performance

In some sense the easy part is to measure the different aspects of performance; brightness, leakage, dispersion and contrast. Owing to the scientific, mathematical design of the AGS Light Performance grading system, the outputs are consistent and repeatable. But creating a standard for each unique diamond shape is challenging. The varying levels of attributes are different among different shapes. Therefore, applying exactly the same standard across different shapes would not result in a meaningful grading scale. The approach instead is to rate princess cut performance against the best performers among that shape.

The process involves studying a wide range of proportion sets. Those combinations are all ray traced and evaluated by looking at the best and worst performers. The grading standard is established at the top end by identifying contiguous ranges of high brightness combined with good contrast, good dispersion and low leakage.

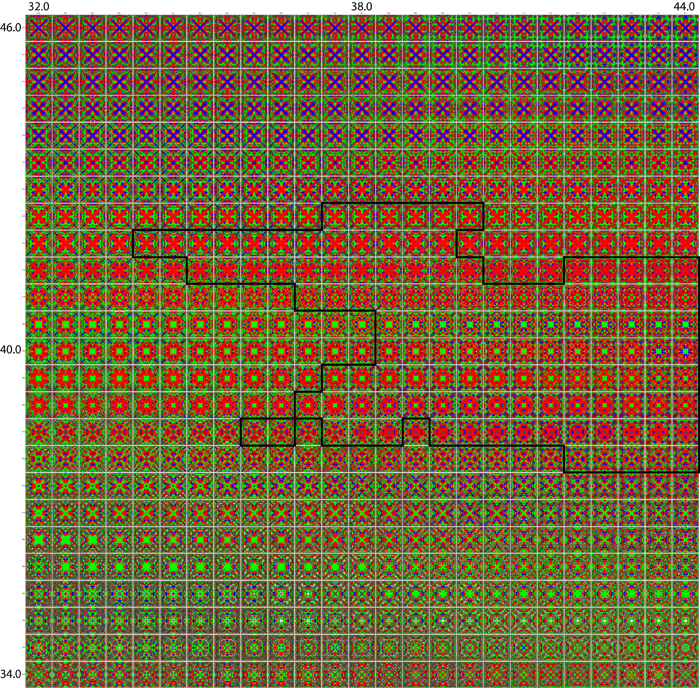

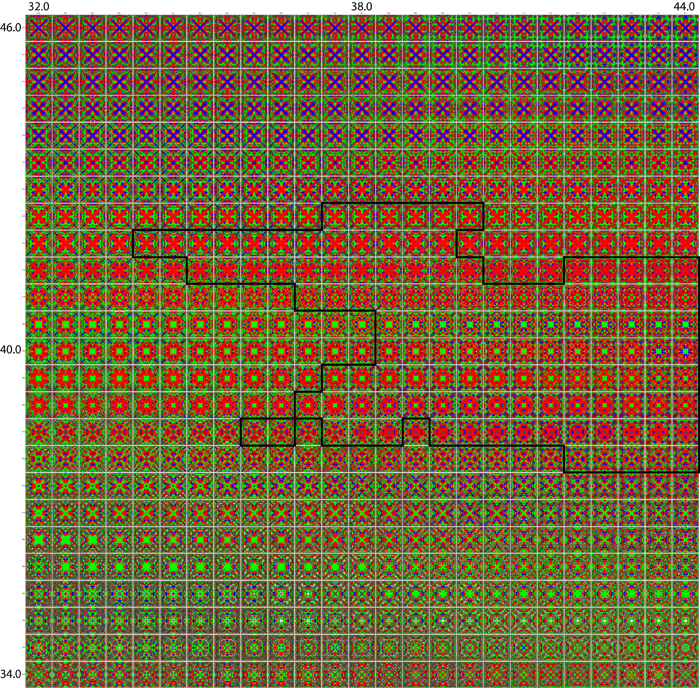

The ASET matrix image in Figure 10 illustrates a range of crown 32-44º (C1) and pavilion 34-46 º (P2) combinations. Those that have potential to make Ideal are outlined in black.

Click image to zoom

Princess ASET Matrix (AGS0 candidates outlined in black)

Figure 10: (courtesy of AGSL)

Proportion Factors

As mentioned above, the light performance software also analyzes the proportion factors of weight ratio, girdle, culet, and durability from the measurements of the 3D scan. If the dimensional “spread” (face up area expressed in square millimeters) of the diamond is not sufficient for its weight, it will receive a deduction for weight ratio. If the girdle is too thin or too thick it will receive a deduction as a result of a weight ratio or a durability issue. If the culet is offset by more than 1% there will be a symmetry deduction. And if crown angles are too low and/or girdle too thin, the stone could be susceptible to chipping or breakage and therefore will receive a deduction.

Length to width ratios vary somewhat in princess cuts. Most well cut stones are relatively square. The AGS model is designed to grade stones with a 1.00 to 1.05 length to width ratio.

When considering the comprehensive array of factors evaluated in the AGSL light performance based cut grading system, it is apparent that diamonds with zero deductions (AGS 0) represent an elite level of cut craftsmanship.

A Word about Measurements

From the dimensions used to communicate princess measurements one can get a somewhat distorted sense of visual size relative to rounds. The footprint or “spread” of a round can be understood largely from its depth percentage, as it derives from total depth, table size and girdle thickness. The depth percentage of the princess is calculated as a ratio of the smallest width to total depth. As a result we commonly see well made princess cuts with depth percentages in the mid 70’s as opposed to rounds in the neighborhood of 60%. But if princess depth percentage were calculated differently, such as using a point to point measurement instead of smallest width, we would see depth percentages much smaller. Traditional princess cuts can also hide weight in pavilion bulge where the P1 angle is higher than it should be for best light performance, so spread of particular princess cannot be understood by depth percentage alone. And while a well made round is approximately 6.5mm in diameter and a princess around 5.5mm, the princess has extended surface area out to the corners. It’s certainly a different look and flavor, but the differential is not necessarily as great as the numbers might suggest.

Generalizations about Ideal Princess Cuts

Some may find these “rules of thumb” about high performing princess cuts to be helpful, bearing in mind they are not hard and fast rules.

• The AGS grading system favors full crowns. It is difficult to achieve a 0 when the crown height is less than 12%. Fuller crowns help the princess cut produce more fire. The AGS System does not mandate fuller crowns to produce more fire. It’s just that better light performance mandates it.

• The AGS system favors smaller tables. It is very difficult to get a 0 with a table size of 69% or greater. Similar to above, too large a table reduces crown area and the light performance suffers.

• The total depth of most ideals falls between 74.0% to 77.0%. (However it is quite possible to achieve 0 outside this range.)

• As a general rule the table size should not exceed the depth percentage.

• The azimuth (index) of the star facet should differ by about 6 to 10 degrees from the azimuth of the corresponding crown facets. This results in a more “squarish” table. When the azimuth difference is large, say 18 or 20 degrees, the table appears more “angular” shape (think of an octagonal stop sign) and the light performance tends to suffer.

• The cut grade system favors pavilions with good facet definition between the pavilion facets, particularly between pavilion 1 and the chevron facets. When the triangular pavilion 1 facet is cut too shallow, then facet definition suffers and the pavilion appears “pointy” rather than full and slightly rounded.

More on Chamfered Corners

A technique called “chamfering” that is sometimes used to improve durability of princess cuts involves putting a very small flat facet on the corners (Figure 11). A similar technique is often used on the culet of round diamonds to prevent chipping. The places most vulnerable to damage on a diamond are at points and where the girdle comes to a knife edge. Because princess cuts are typically set with prongs on the corners, the setting process involves elevated risk to stones that are cut in the conventional way with sharp corners.

Figure 10

Chamfered corner princess cuts are accepted for cut grading by AGSL provided they are small enough not to change the overall shape of the diamond. Chamfered corners are normally not called out on an AGS report.

*In the opinion of the author, this technique should be more widely used by manufacturers as it would improve durability of princess cut diamonds.

Market Perspective

From the time the princess cut first entered the market until the AGSL light performance cut grade for princess was introduced, there was really no cut quality standard for the shape. As a result, most were cut with the primary goal of retaining weight. Making the most beautiful princess was secondary to getting the most carat weight possible out of the rough, primarily because the technology to determine how to make them had not been invented yet. Today, the broad market is still much the same. There are currently only a handful of diamond manufacturers specializing in top cutting of princess cuts.

Because most diamonds are certified by GIA and because GIA has so far elected not to provide an overall cut grade on princess cuts, most cutters have no incentive to change their manufacturing practices or marketing strategy. The result is a market full of princess cuts that while pretty, do not express the full potential for the beauty aspects that most consumers value in a diamond.

As more consumers have the opportunity to see AGS Ideal princess cuts and learn about the their superior light performance, the market will begin to see a change in the approach that manufacturers and dealers take with respect to this very popular diamond shape.

Final Thoughts

The AGSL is widely considered the world leader in diamond cut quality analysis. Their comprehensive light performance grading system is scientifically rigorous, consistent, repeatable and adaptable to any diamond shape. The groundbreaking work they did on round brilliant cut diamonds focused new attention on the importance of diamond cut. It evolved from a 2 dimensional, proportion based system to one based upon ray tracing in 3 dimensions and calculating the effects of every facet on the diamond’s performance. In the process, the research served to create a new segment of the diamond market interested in top cut quality. This led the GIA to introduce their cut grade system for rounds which served to further elevate cut quality as the most important of the 4 Cs.

The work AGSL has done in the evaluation of the princess cut has likewise led the way to greater understanding of the beauty elements of this popular shape. And it has begun to change the way some manufactures approach their princess production. When this “philosophical” change away from weight retention and toward beauty is adopted by mainstream cutting houses, consumers will have far more high performing princess cuts to choose from than they do today.

by Bryan Boyne, GG (GIA), RJ (AGS)

Vice President

Whiteflash Inc.

Read the other installments of this series:

Part One: Laboratory Graded Diamonds – What are the benefits for the consumer?

Part Two: Diamond Laboratory Process- Basic Functions and Procedures

Part Three: AGS Laboratories – Color Grading of Diamonds

Part Four: AGS Laboratories – Clarity Grading of Diamonds

Click here to discuss on the Forum