Here Drena is standing behind a mobile Disco, available for weddings and party hire etc. These guys would not fire it up, even though I offered a tip – business must be good!

This cute child in the car next to us was from a very middle class family; there are more wealthy people in India than the entire population of Australia. We have been to shopping centers that are just like Western Malls, and it is apparent every visit that the middle classes of India are growing.

When I first visited India as a back packer in 1974 I was unable to stay a whole day in Bombay (as it was called then); it was just too depressing. There were starving people sleeping everywhere on the streets and in the morning I am sure that many of them had not woken up. It was desperate and depressing. But now the economy is picking up and there seems to be paid work for everyone who is prepared to work. It seems that even the beggars at the big intersections (as shown) and around tourist hotels have informal organizations with ‘pimps’ and zones. Apparently there are some benefactors who put on a meal a day for legitimate beggars, but many people here are upset that this attracts lazy people who squat under the road overpasses (it never gets very cold in Bombay); perhaps they are the equivalent of our dole bludging surfers who move up and down the east coast of Australia as the weather changes?

Begging at major intersections is very common. I gave the one on the left 10 rupee’s for posing, and the one on the left ran out and nearly got killed for her piece of the action.

Here is a shot of the +100 year old Palace section that we stay in. There is a new glass tower style next door to the right – but the old part has lovely high ceilings.

The plate of a mostly devoured meal was at Trishna – the most amazing fish restaurant – masala (like Chiken tikka) flavored calamari and a piece of Skewered Pomfrit fish (like a fat flounder) cooked in a butter black pepper in a tandor oven. We went back 3 times in a week for these same 2 dishes (and giant prawns and crab). It is a 15 minute walk from the Hotel. There is also a fab Lebonese place on the top of the new tower 🙂

Some of the paintings and sculpture in the Taj Mahal Bombay hotel passages and on our floor. We were very impressed with the art in Delhi too.

A buying room – it is about the size of a large toilet or a small bathroom, and doubles as a dining room as we can see with Drena and Tony, the GM of the chain-store she works for, with the guy who heads the sales office of this company. They originally were Argyle Sightholders, and then became clients of BHP as well. So the diamonds we buy from them are Argyle champagne (now wholly owned by Rio Tinto) and Rio’s DiaVik white diamonds and their new African mine (can’t remember the name??). They track each diamonds origin, so we know if the stone is Canadian and from which mine etc. They have also subscribed to the Canada mark program.

Here we are in another suppliers office– there must have been about 3 or 4 kilos of diamonds in each bag. At 5,000 carats per kilo – that is a lot of diamonds. They are all very cheap TLB (TopLightBrown) small goods. This company produces about what is on the table each day!!!

Here we are in another suppliers office– there must have been about 3 or 4 kilos of diamonds in each bag. At 5,000 carats per kilo – that is a lot of diamonds. They are all very cheap TLB (TopLightBrown) small goods. This company produces about what is on the table each day!!!

Opera House Diamond District

The streets around the diamond market (opera house district) where all the brokers or couriers hang out – you can see one deal being done in the street in front of a 5 star restaurant. Yes it is diamonds, not drugs. There is also a shot of some after market wiring in an adjoining building.

Indian Jewelry Stores

A jewelry counter in a department store – just like a cosmetics counter in a regular department store – there were 7 brands with a showcase or 2 each and 14 staff – 2 for each company. They were not happy about us taking the photo. Not a lot of business going on. The jewels are all on consignment and the staff are employed by the jewellery manufacturer.The manufacturers are all diamond companies – as the companies have grown, they have opened jewellery manufacturing divisions. Many are set up in the SEEPZ district near the airport; this is a duty free zone and the latest tools and equipment are used in state of the art factories. Most budget priced US jewellery comes from here (although China is growing too). Naturally many of these companies would like to establish a brand presence here in India for their own prestige and as part of the requirements of De Beers, Rio and BHP – that they establish downstream markets and alliances rather than the earlier practice of selling their polished goods on open bourses in Antwerp etc. Sales on a bourse are like shares – buyers and sellers work through brokers and never know each other; this means there can be no value adding by manufacturers finding out their customers specific requirements and fulfilling them. But from what we have seen so far the Indian ‘branding’ is a copy cat business model leaves a lot to be desired. The sales people are nice kids, but have no idea about jewellery or how to sell. The styles are all almost identical – no company seems to be prepared to differentiate themselves – but then I guess that is the Asian way.

GIA and off to Surat

After a week of buying in Mumbai, Drena and Tony flew off to Bangkok trade fair. I finished off a bit of buying and did an interview with one of the local trade mags before heading to Surat, 4 hours train ride north, to where all the diamonds are cut.

This was my third time to Surat to work with Mr. Janak Mistry, CEO of Lexus. Janak makes diamond manufacturing machines and designs factory processes. Janak and one of the manufacturers who attended the IDCC diamond cut conference that we hosted in Moscow. Kishor came down to Mumbai with Janak and the three of us went to a presentation by GIA president Bill Boyajian (center left with the shorter Martin Rapaport to his right). There was little news in the presentation. Bill was rather shocked to see me, Martin was pleasantly surprised; “what’s the cut geek from down-under doing here?”. Later we caught the 11.30pm sleeper train to Surat and I arrived at the Horrid Day Inn hotel at 4.30am for a nap before pick up at 10.30am.

Note people napping at Bombay Central railway station, and a rain cover over a shopping center, then the new Lexus head office and factory (the 3rd factory).

Lexus

Pictured above is Janak and below is younger brother Uptal (computers). Below is the youngest brother, Kamal (optics), who is working on Sergey’s latest OctoNus® product. Helium Rough is the newest scanner that can identify the size and location of inclusions in rough diamonds and plan for cutting around them to produce higher clarity diamonds. The machine was being tested and has the cover off. I have deliberately blurred the image unfortunately because this technology is top secret.

The shot on the right shows a diamond model (brown) on the scanning table. When the polished diamond model(s) have been planned the black circular light thing between the diamond and the screen is a high power laser that burns a small line all around the stone so the sawyer knows where to cut the stone (most diamonds are sawn and 2 polished diamonds are produced from the 2 halves).

Machines for Cutting

Here we can see a rough stone that has been planned using Helium Rough. Two rounds are to be cut around the tiny inclusions. After sawing, the stone would be put on a machine like this one, an auto bruter, which is a type of lathe that has 2 diamonds mounted on the ends of the small steel shafts in very bottom of the top left photo. They are then profiled and shown enlarged on the computer screen above. They are ground on each other until they are fully rounded. Janak is the main supplier of auto-bruters in Surat. Part of his philosophy is to specialize in machines that have computer guidance. These are all hooked into one huge LAN network that enables management control of each step of the polishing program. Sergey’s scanner planners are designed with this process control system in mind.

After bruting, Lexus customers use an auto blocker (the next side and plan photo’s), This computer controlled machine polishes the main facets on 4 diamonds at a time – each is held on 4 heads that sit on one polishing wheel. Next the stone goes to a hand polisher or Brillianteer, who polishes the final facets and makes precision adjustments using the scanner image shown that is equipped with DiamCalc and ideal-scope software so they can see how the final stones light return and leakage will look after polishing.

A Day at Lexus

Shown above is some experimentation with the new Rapid Ideal-Scope capture set up, some of the Lexus team, the lower ground factory floor, and Janak at work at his desk. The office is very slick and he insists we use the lift; after all that is why they have it for just 3 floors!

On an average day Janak gets many clients asking for specialist help and assistance. Since he is a formally trained engineer (in Germany) and well experienced now in the diamond industry, he is often called upon to solve problems. These two guys had bought the 4 sawn pieces of two rough diamonds for a consultation. 3 of the pieces had developed large inclusions after sawing and they were trying to find out why. Janak showed them a polariscope – a standard gem instrument for checking if there is stress in diamonds. There was no stress in the 3 that had developed inclusions after sawing – but the one that had not did have the tell tale ‘tatami patterns’. Janak explained that the inclusions that appeared were the result of a release of the stress – and that is why the ? with no new inclusions still had its stress color patterns showing up. The answer is to laser saw (burn) so there is no mechanical stress, or cleave (break) the stressed stones parallel to the plane (octahedral) that contains the stress.

Factory Visits

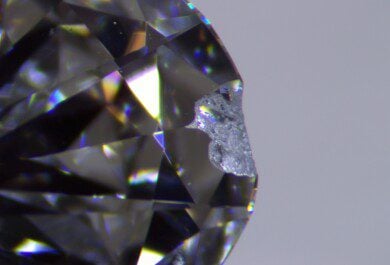

This is a 15ct D IF Hearts and Arrows that was polished while I was in Surat. And next are a series of photo’s of different factories all mixed up for anonymity. What you very quickly learn in this place however is the amazing thirst for knowledge and ways to improve anything and everything. That is why De Beers recently upset Belgian, New York and Israeli cutters and gave so much more of its rough business to Indian manufacturers. These guys are ‘manufacturers’ – they are not ‘cutters’ or ‘polishers’.The thirst for new technology and machinery led one manufacturer who was not satisfied with an 18 month wait for a German machine, to simply buy 51% of the company. There are companies with Ramon spectrographs, spectrophotometers and all the lab gear for detecting synthetic and HPHT treated diamonds. There are grading rooms set up with the very best microscopes and intensively trained staff for grading Flawless and VVS1 diamonds using the HRD method; these guys do only 4 to 6 stones a day.The 2 ‘blocked out’ diamonds in the stone paper have been sawn with a state of the art new laser saw. The black is carbon from the vaporization burning process. Underneath the black are nice diamonds that now just need polishing or as we say ‘brillianteering’.

Some Factory Buildings

Another leading manufacturer is into minimalist architecture; he read and researched the styling extensively himself and built a factory with no painted surfaces in the building.

This is one of the first of the new factories built in Surat.

This last factory is run by the only person in Surat with an espresso coffee maker 🙂

Most of these companies are De Beers Sightholders, i.e. they go to London every 6 weeks to collect a shoe box full of rough diamonds, assorted as best as De Beers can, to share out the desirable and the not so desirable rough diamonds from their mines and those of the mines that are sold through their ‘co-operative’ (30% and 20% of the worlds diamonds respectively).

Remember that 110 years ago De Beers was originally founded by Cecil Rhodes (as in Rhodes Scholars and Rhodesia) as a miners co-operative. Around 1,000 miners were working the on Big Hole and being ripped off by the European buyers. It was only in the 1930’s depression, that the vision of Sir Ernest Oppenheimer led to his purchasing the shares from the miners families; they did not have the guts or belief in diamonds to fund the continued buying of rough. The other investors did not believe the market would rebuild for many years. Oppenheimer did the classic thing – made a big punt – and had to make it work. Within a decade he had employed top advertising and PR guru’s and who came up with the famous line – “A Diamond is Forever”. The rest is of course history. BTW the name De beers came from the name of the farm that the Big Hole was found on. There was never a Mr. & Mrs. De Beers.

AGS 0 Princess

Around Town

As you drive around you see all sorts of strange things. This was not so unusual, two guys riding on a Tuk Tuk piled high with fabric (the other major product from the industrial Surat). We were just behind this Tuk Tuk at a narrow round-about intersection, when I noticed one of these guys nearly fall off. To save himself, he jumped off onto a similarly laden mini truck, regained his balance, and then jumped back on to his vehicle. Neither vehicle slowed down.

Another new factory being built – I doubt Aussie or US builders would do this.

I took these 2 photo’s on the last day in Surat at the Horrid Day Inn. The clocks show the ‘not quite right’ (NQR) aspects of India. The other is a ‘stitch’ photo from the room window.

The star student

I visited many other companies with older facilities (who are building new beaut factories too) that I had visited once or twice before in 2003 or 2004. We discussed many Cut and marketing related issues. I had for instance visited many of their marketing offices in Mumbai and in some cases had asked for stones that exhibited various effects of painting and digging minor facets to be sent to Surat for discussion. Many of these companies are preparing to put Gem Adviser files and ideal-scope and realistic photo images on to their B2B sites. This will make it easier for consumers to know the diamond’s cut quality. Maybe retailers too will catch on? Some of the firms are also interested to use the ideal-scope sales system in their Indian stores. Of course there was more – but I would have to kill you if I told you.

Above is the only person who I will name and photograph. Siddhartha is our star diamond cut student. He first learned about the ideal-scope and DiamCalc from Janak and has crawled all over Ideal-scope and MSU websites. I first met him 2 years ago and he was the nominated spokesperson and on all the panels at the IDCC conference in Moscow last year.

Siddhartha developed a system for the Brillianteer’s where they plan the stone using a profile scan like the one shown here. They decide on the most efficient proportions for the best yield, and then they must choose one of 16,000 sets of parameters to vary either the crown, pavilion or table sizes. These 16,000 combinations of proportions will achieve 97% or better light return as defined by DiamCalc. This of course means the stones will all look great through the ideal-scope. I know that this is true because for the first time ever, when I visited their Mumbai office I bought every stone in a parcel (about 20 stones). This is the first time I have ever seen a parcel where I could not reject a single stone for cut quality with the ideal-scope.

He is turning out diamonds with altered minor facets in a way pioneered by one of the most expensive brands in USA and Japan. As they say in marketing school – relying on product quality as a point of differentiation is a bad business model. The other part of this story that makes me particularly happy; most of the business of this firm is 90% lower end off colour lower clarity. These are the goods that do not get certified and often end up in the Mall’s and chain stores of the world. My crusade to improve diamond cut quality has always been more intent on improving the average end of the markets diamond beauty. Many Pricescope discussions center around the definition of super ideal and super doper ideal cut diamonds. Trying to squeeze an extra 1% or 2% more life and fire out of each diamond has never been my goal. I am very happy now; I believe about close to ? of the worlds diamonds are now cut to a very acceptable standard. Given we started at around 90% being lousy – we have really come a long way in just 6 years.

Related Articles

Article Series

This article is part 2 of a 3 part series. Other articles in this series are shown below:

- The Palace on Wheels – The adventure

- Diamond Adventures in India

- USA Adventures June 2005

Here we are in another suppliers office– there must have been about 3 or 4 kilos of diamonds in each bag. At 5,000 carats per kilo – that is a lot of diamonds. They are all very cheap TLB (TopLightBrown) small goods. This company produces about what is on the table each day!!!

Here we are in another suppliers office– there must have been about 3 or 4 kilos of diamonds in each bag. At 5,000 carats per kilo – that is a lot of diamonds. They are all very cheap TLB (TopLightBrown) small goods. This company produces about what is on the table each day!!!