P

pricescope

Guest

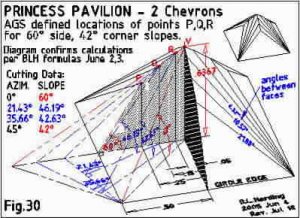

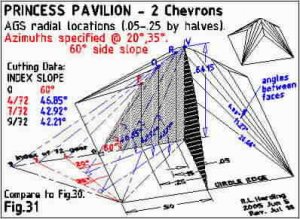

Many thanks to Bruce Harding (aka beryl, the author of Faceting Limits and "Diamond Design" Revisited) for his new article Grading the Princess Cut.

Date: 8/13/2005 6:08:02 PM

Author: Garry H (Cut Nut)

...When you imnport a real scan into DiamCalc there is a little known option called ADVANCED, which is normally grayed out. the tab is in the middle of the right side area just above MAP. If you open that tab you can cut or uncut facets. I took a stone and (cant remeber - did i add or remove) recut the chevrons.

Probably a good catch, Garry. I didn't think of that as the 'representation' issue.

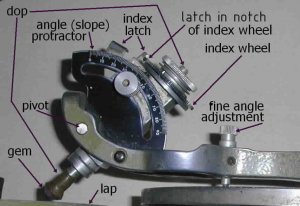

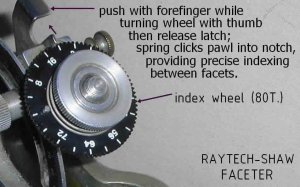

Thats what it looks like gary, sometimes the index wheels are also color coded on the side, depending on who made them.Date: 8/14/2005 9:57:19 PM

Author: Garry H (Cut Nut)

I see if I get some time tonight Beryl

Here is a picture of the type of critical gadget that is an index wheel for a round brilliant pav facets (I think)