belgian_mussels

Shiny_Rock

- Joined

- Mar 1, 2008

- Messages

- 113

Hi All,

I hope you are well. I have recently bought an engagement ring from a Sydney based jeweller. Jeweller has 35 years of making custom jewellery as well as for retailers.

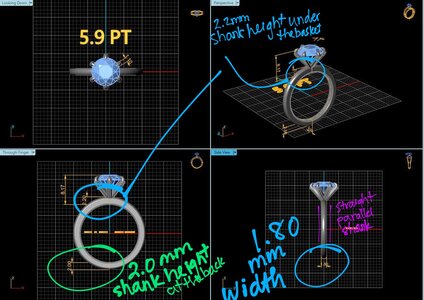

We have asked for a 2mm shank. But the jeweller made it 1.7mm wide ring and 2mm in thickness. Material = 18k white gold. Stone: 1.7ct.

Attached are some images. When I first gotten the ring, I thought the band is very skinny and potentially the prong head may fall off from the ring. But the jeweller said it will not as it has a pin welded to the ring.

Is this a well made ring such that it should not break? Ps: I don’t wear it when doing strenuous activities. Your thoughts are greatly appreciated. Thanks so much.

I hope you are well. I have recently bought an engagement ring from a Sydney based jeweller. Jeweller has 35 years of making custom jewellery as well as for retailers.

We have asked for a 2mm shank. But the jeweller made it 1.7mm wide ring and 2mm in thickness. Material = 18k white gold. Stone: 1.7ct.

Attached are some images. When I first gotten the ring, I thought the band is very skinny and potentially the prong head may fall off from the ring. But the jeweller said it will not as it has a pin welded to the ring.

Is this a well made ring such that it should not break? Ps: I don’t wear it when doing strenuous activities. Your thoughts are greatly appreciated. Thanks so much.

300x240.png)