klrrrr

Shiny_Rock

- Joined

- Aug 5, 2019

- Messages

- 433

One of the tragedies of shopping for jewelry online is losing out on the age-old, tactile experience of in-person shopping. Combine that with the fact that we're viewing tiny things on large screens, and you have a recipe for unrealistic expectations.

I was trying to visualize the size of a stone I have on hold (stone details here). Despite using the online ring-size simulators, Stone Algo, etc, I didn't have a good sense of what it would feel like on my finger. I have never owned a deep old miner, and was concerned about the depth not suiting my lifestyle. Without the opportunity to view in person, I needed to find a solution.

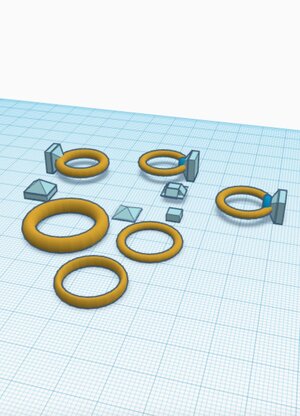

I'm fortunate to live in a city with an expansive library system that includes 3D printers. Last night, I taught myself how to do basic CAD work in TinkerCAD, building a few different options for evaluating the diamond. Someone with better CAD skills could have done something more elegant, but this was fine for my needs:

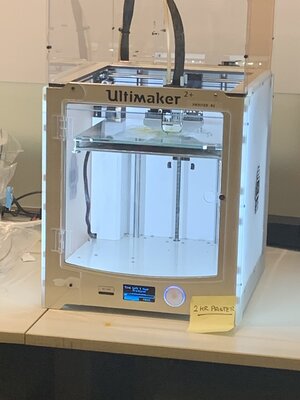

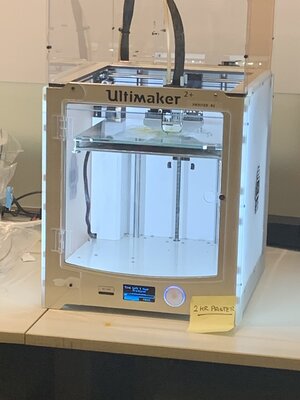

I was fortunate to secure a printing window this afternoon:

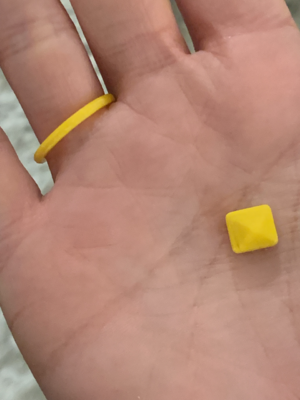

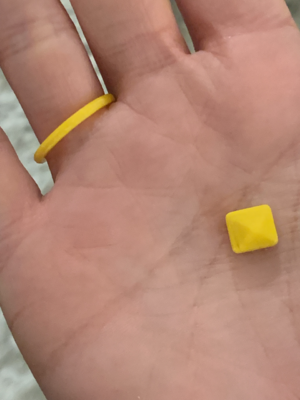

Less than 24 hours after lightning struck, I have a crude mockup of the stone that I can balance precariously on my finger

Pavillion view (had to gorilla glue two pieces together):

Now it wasn't entirely successful. The rings on settings failed miserably because they were accidentally printed without supports. Back to TPL tomorrow for round two!

I know those working with wonderful jewellers often have the opportunity to view their WIP items as a 3D object, and this experience made me feel that more people should have the opportunity to feel before they buy. Maybe there's a business opportunity nested in here somewhere.

I was trying to visualize the size of a stone I have on hold (stone details here). Despite using the online ring-size simulators, Stone Algo, etc, I didn't have a good sense of what it would feel like on my finger. I have never owned a deep old miner, and was concerned about the depth not suiting my lifestyle. Without the opportunity to view in person, I needed to find a solution.

I'm fortunate to live in a city with an expansive library system that includes 3D printers. Last night, I taught myself how to do basic CAD work in TinkerCAD, building a few different options for evaluating the diamond. Someone with better CAD skills could have done something more elegant, but this was fine for my needs:

I was fortunate to secure a printing window this afternoon:

Less than 24 hours after lightning struck, I have a crude mockup of the stone that I can balance precariously on my finger

Pavillion view (had to gorilla glue two pieces together):

Now it wasn't entirely successful. The rings on settings failed miserably because they were accidentally printed without supports. Back to TPL tomorrow for round two!

I know those working with wonderful jewellers often have the opportunity to view their WIP items as a 3D object, and this experience made me feel that more people should have the opportunity to feel before they buy. Maybe there's a business opportunity nested in here somewhere.

300x240.png)