Hi everyone! I’ve picked a 2ct round diamond and currently in the process of ring design with my jeweler. Initially we agreed on making a CAD drawing first, but the jeweler skipped the step and sent me some pictures of the wax mold directly. I would love some opinions on this wax mold, and how I should communicate with the jeweler so the ring is closer to what I expect.

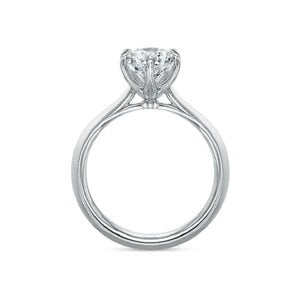

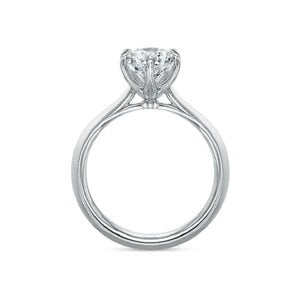

Here are some pictures of the design I want. The only modifications would be: 1) Prongs at EW orientation, 2) No knife edge, and 3) Petite rounded tab prongs.

Here are the pictures of the wax mold:

Overall, I think the wax mold is close to what I want, but the entire mold looks bulky and lacks some details that I’ve communicated to the jeweler before. For example, the 6 prongs aren’t as tapered towards the top, the prong shape doesn’t look like a rounded tab, the shank isn’t as tapered towards the centre, and the cathedral arms aren’t soldered to the EW prongs.

I wonder if it’s normal for wax mold to lack the presentation of details? Is the wax mold made to my finger size, so I can try it on with my stone on it?

Is this considered a high setting? My work does require gloves wearing, should I ask for the stone to be set lower for a practical reason?

Any opinion/advise is appreciated. Thank you very much!

Here are some pictures of the design I want. The only modifications would be: 1) Prongs at EW orientation, 2) No knife edge, and 3) Petite rounded tab prongs.

Here are the pictures of the wax mold:

Overall, I think the wax mold is close to what I want, but the entire mold looks bulky and lacks some details that I’ve communicated to the jeweler before. For example, the 6 prongs aren’t as tapered towards the top, the prong shape doesn’t look like a rounded tab, the shank isn’t as tapered towards the centre, and the cathedral arms aren’t soldered to the EW prongs.

I wonder if it’s normal for wax mold to lack the presentation of details? Is the wax mold made to my finger size, so I can try it on with my stone on it?

Is this considered a high setting? My work does require gloves wearing, should I ask for the stone to be set lower for a practical reason?

Any opinion/advise is appreciated. Thank you very much!

300x240.png)