JohnQuixote

Ideal_Rock

- Joined

- Sep 9, 2004

- Messages

- 5,212

Re: Swindling...Brian has a section in the PriceScope tutorial which addresses that, linked here.

Garry, this is a most important point.

Diamonds cut on these large process lines, as you put it, often result in the imprecisions illustrated in this whole discussion. This floods the market with phony, so-called hearts & arrows cuts and dilutes standards.

Most machines are used for blocking (too many problems cutting the whole stone mechanically, especially in larger sizes). It’s possible for a machine to complete a stone, especially with smaller stones, but in most facilities brillinteering is done by hand.

I, like you, am also in awe of the skill that precision cutting requires.

I believe the cutter who cleans up the diamond, removes inclusions, retains the weight AND delivers perfect patterning has the most skill of all. He is not making adjustments merely for the sake of retaining weight – he is delivering physical symmetry as it was intended in the initial design of the diamond. True symmetry and resultant patterning is not an accident. It is the goal when starting out.

Brian presented a discussion of grading for Hearts & Arrows diamonds at the IDCC, but it''s obvious that labs have their hands full and will not get into it anytime soon. Therefore, it''s up to those of us who interact, appreciate and have a passion for precision to communicate in forums such as this one.

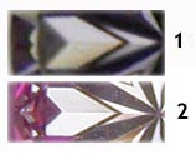

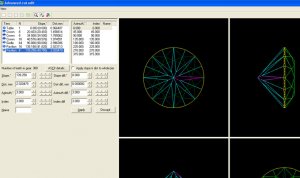

I will post a series of what I term "Phony," "Near-True" and "True" hearts photographs to illustrate different levels of precision which are out there. This may help separate the “auto-dialit drones” from higher standard stones with acutely good craftsmanship.

Date: 11/26/2004 9:447 PM

Author: Garry H (Cut Nut)

It always needs to be stated - there is more skill in swindling like this, than in simply cutting H&A''s on an auto dialit or process line. i am constantly in awe of the skill these people exhibit. (and btw they are often teams of several people doing each part of a process).

Garry, this is a most important point.

Diamonds cut on these large process lines, as you put it, often result in the imprecisions illustrated in this whole discussion. This floods the market with phony, so-called hearts & arrows cuts and dilutes standards.

Most machines are used for blocking (too many problems cutting the whole stone mechanically, especially in larger sizes). It’s possible for a machine to complete a stone, especially with smaller stones, but in most facilities brillinteering is done by hand.

I, like you, am also in awe of the skill that precision cutting requires.

I believe the cutter who cleans up the diamond, removes inclusions, retains the weight AND delivers perfect patterning has the most skill of all. He is not making adjustments merely for the sake of retaining weight – he is delivering physical symmetry as it was intended in the initial design of the diamond. True symmetry and resultant patterning is not an accident. It is the goal when starting out.

Brian presented a discussion of grading for Hearts & Arrows diamonds at the IDCC, but it''s obvious that labs have their hands full and will not get into it anytime soon. Therefore, it''s up to those of us who interact, appreciate and have a passion for precision to communicate in forums such as this one.

I will post a series of what I term "Phony," "Near-True" and "True" hearts photographs to illustrate different levels of precision which are out there. This may help separate the “auto-dialit drones” from higher standard stones with acutely good craftsmanship.

300x240.png)