rubybeth

Ideal_Rock

- Joined

- Nov 12, 2007

- Messages

- 2,568

HopeDream|1322026822|3067451 said:Undercover 999

Is there any reason you're not just finishing your CNC waxes for casting? - (surely all wax melts)? Is cnc very difficult to finish? Could you CNC a castable wax? I'm not sure that making a rubber mold is necessary - you might be doing more work than you have to. (Unless you want to make your fiance 100 rings, all the same.)

I can see you're definitely making progress!

Lady_Disdain|1322106645|3068086 said:It is very interesting to watch your progress! Remember to keep the workshop well ventilated while casting.

Have you checked if your fiancee has nickle sensitivity? It is more common than people imagine, which is why nickle white gold is banned in Europe and why nickle was voted Allergen of the Year in 2008 by the American Contact Dermatitis Society.

HopeDream|1322191670|3068502 said:Awesome pics!

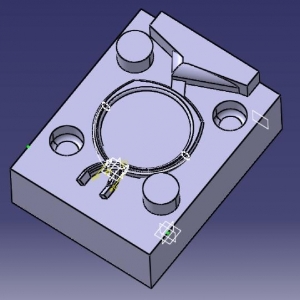

I was discussing your project with my fiance and he suggested that instead of trying to cut out a positive image of your ring with your CNC machine, you could have it cut out the negative image of your ring, basically have it cut you a ring mold out of metal/heat resistant plastic, and then pour wax into the cut mold to shape the wax - if you had 2 pegs on one side of the mold and holes for the pegs on the other side of the mold it would line it up perfectly. You could even pre-cad the sprue onto the ring, and have it as part of the shape of your mold.

HopeDream|1322191670|3068502 said:The youtube casting prcedure 1-17 clips will give you a good idea of the investing process and brief use of a casting machine - note the heavy use of a vaccuum chamber to eliminate air bubbles : http://www.youtube.com/watch?v=EpHDYpgP9Fw

This is also a nice and instructive series of clips on the casting process - I think they use a vaccuum caster: http://www.youtube.com/watch?v=C7lrNBOtgLY

For the casting itself you might want to see if you can use someone else's shop. These set-ups get ridiculously expensive :http://www.master-machines.com/melting_casting_machinery.htm . You could still be doing all the work, I just wouldn't want you to shell out for a set-up you'd only use once (or twice?).

sonnyjane|1322243444|3068685 said:Just thought of something - are you taking her ring size into account while doing this project? I only ask because it'd be a shame if you really did every step of this process without help, but then still had to take it into the jeweler to size it properly once you were finished!

HopeDream|1322291287|3069027 said:Nice setup!

How about a centrifugal caster? http://www.americanjewelrysupply.com/products/casting/centrifugal2.html

http://www.ajstoolsonline.com/mysto...ine/neycraft-centrifugal-casting-machine.html You wind up the caster and lock the mechanism, You mount the investment flask horozontaly, lined up beside the crucible, heat your metal in the crucilbe with an oxy-acetaline torch, and then when the metal is molten you release the mechanism and the molten metal is spun into the mold.

Hopefully heating to the correct temp, and spruing from the band will help you deal with the porosity issues. If you still have issues after you change your technique, you may have to go to a more formal casting apparatus.

Make sure you take lots of pictures from your journey and make your fiancee a "how I made your ring" journal/scrapbook - I bet She'll love it and love to show it to friends and family.

I'm glad the "ring bite" on your hand is starting to heal.

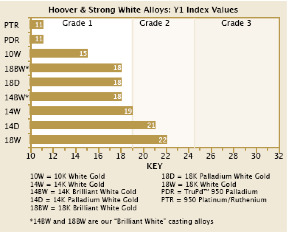

kt Gold Palladium Silver Copper Zinc Nickel

18 75 20 5

18 75 15 10

18 75 10 15

18 75 10 10.5 3.5 0.1 0.9

18 75 6.4 9.9 5.1 3.5 1.1

18 75 15 3.0 7.0

14 58.3 20 6 3 1

14 58.5 5 32.5 20.5 1.4

10 37.5 52 4.9 4.2 1.4kt Gold Palladium Silver Copper Zinc Nickel

18+ 80 20

10 37.5 12.5 23 27Sounds pretty good...An alloy of palladium 20 parts, gold 80, is white, hard as steel, unchangeable in the air, and can, like the other alloys of palladium, be used for dental purposes.

Alloys of gold, copper, silver, and palladium have a brownish red color and are as hard as iron. ... The composition used in the Swiss and English watch factories consists of usually of gold 18 parts, copper 13, silver 11, and palladium 8.

kt Gold Palladium Silver Copper Zinc Nickel

18 75 24.5 0.5

14 58.3 ?? ?? ??

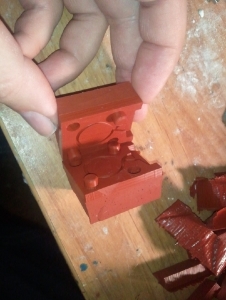

Undercover999|1322879006|3073249 said:Then the investment is prepped and poured and the whole thing into the vacuum chamber for debubblificatorationing.

Lady_Disdain|1322923943|3073415 said:Is there a reason for you to mix your own alloy instead of buying casting grain? Alloys can be very finicky and minor variations can have a huge impact on casting suitability (such as porosity and doing a good, full pour). If you were going for a traditional alloy such as 18k yellow, green or rose, then it is more straightforward but palladium gold isn't quite as simple. Also, casting is more sensitive than fabricating, where manipulation of the metal will solve a lot of problems.