- Joined

- Jan 7, 2009

- Messages

- 10,479

Re: A hanforging journey - Five-Stone Eight-Prong trellis by

Hi Guys- hopefully it's ok if I handle Charmy's questions:

First of all, it's not possible to comment on finish at this point in the job- final polish is done- by hand- and the difference between a great polisher, and a very good one is incredible- it seems like a simple part of the process- but don't under-rate it's importance.

By all means, we'll check the final polish very carefully- however a concern about the transition being jagged is directly related to this.

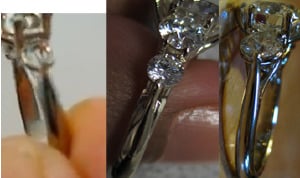

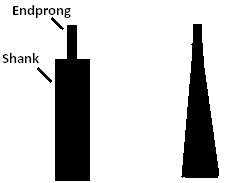

Second of all, on this point- is the prong.

Right now we're looking at a wire sticking straight up. Once the stone is seated, and the prong finished, this entire area will look different.

IN terms of roundness- part of this aspect is also related to polish.

However we also need to have some character line at the outside edge of the shank for continuity- it will really make the prong look far more integrated.

Since we've been looking "inside" this process- and seeing things the end user usually does not- we get a more thorough perspective.

For example, there's two totally independent designs- the top, and the shank.

Different manufacturing process- as well as structure. We can do a hand forged shank- but for this project it would not have provided the desired results.

What this means is that an important aspect of this particular ring- and many others- is integrating different parts, that need to be made differently.

The profile of the shank will go a long way towards tying this all together.

Last thing is that it's far more informative looking at the moving pictures as opposed to a static one- sometimes a shadow can make the ring look different than it actually does.

ETA- thank you for taking your time to assist Charmy- for many reasons, this is a very important ring- so all input is gratefully accepted!

Hi Guys- hopefully it's ok if I handle Charmy's questions:

First of all, it's not possible to comment on finish at this point in the job- final polish is done- by hand- and the difference between a great polisher, and a very good one is incredible- it seems like a simple part of the process- but don't under-rate it's importance.

By all means, we'll check the final polish very carefully- however a concern about the transition being jagged is directly related to this.

Second of all, on this point- is the prong.

Right now we're looking at a wire sticking straight up. Once the stone is seated, and the prong finished, this entire area will look different.

IN terms of roundness- part of this aspect is also related to polish.

However we also need to have some character line at the outside edge of the shank for continuity- it will really make the prong look far more integrated.

Since we've been looking "inside" this process- and seeing things the end user usually does not- we get a more thorough perspective.

For example, there's two totally independent designs- the top, and the shank.

Different manufacturing process- as well as structure. We can do a hand forged shank- but for this project it would not have provided the desired results.

What this means is that an important aspect of this particular ring- and many others- is integrating different parts, that need to be made differently.

The profile of the shank will go a long way towards tying this all together.

Last thing is that it's far more informative looking at the moving pictures as opposed to a static one- sometimes a shadow can make the ring look different than it actually does.

ETA- thank you for taking your time to assist Charmy- for many reasons, this is a very important ring- so all input is gratefully accepted!

300x240.png)