- Joined

- Jan 11, 2006

- Messages

- 58,582

Hopefully not since it could still come back VS2 or an eye clean SI1. My eyes are too old to pick up any inclusions.diamondseeker2006|1406770776|3723485 said:Wow, DF, that is so exciting to see the diamond at this stage! You'll never see the inclusion once all those little facets are cut!

Nope, you know as much as I do...kenny|1407706938|3729787 said:Someone pour me a glass of wine.

DF, I thought your ship came in.

Dancing Fire|1407717156|3729907 said:... did Jon shipped you my Octavia by mistake?kenny|1407706938|3729787 said:Someone pour me a glass of wine.

DF, I thought your ship came in.

kenny|1406832955|3723899 said:Thanks for the pics, Yoram, Jonathan, and DF.

I think it is fascinating and awesome to see in-pocess pics as the facets are being polished.

Question for anyone with expertise:

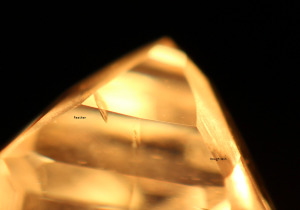

Could the feather have been a surprise because those windows (polished onto the rough early, as shown in the pic below) only permitted a view of the feather from the wrong angle, or an angle that 'hides' the feather ... much like viewing a piece of paper from the side?

Or is there some light-bending property of diamond that can make inclusions in certain locations hard to spot given only a few small windows on the diamond's frosty surface.

kenny|1406832955|3723899 said:Thanks for the pics, Yoram, Jonathan, and DF.

I think it is fascinating and awesome to see in-pocess pics as the facets are being polished.

Question for anyone with expertise:

Could the feather have been a surprise because those windows (polished onto the rough early, as shown in the pic below) only permitted a view of the feather from the wrong angle, or an angle that 'hides' the feather ... much like viewing a piece of paper from the side?

Or is there some light-bending property of diamond that can make inclusions in certain locations hard to spot given only a few small windows on the diamond's frosty surface.

Hi Kenny, basically all of your questions are valid and then some...

In our specific case, it was a completely see-through feather which originated from a single plane (most feathers originate from multi-planes which causes them to be more easily visible when studied. These single-plane see-through feathers depending on their size/position will allow the light path through the feather without any light bending/reflections causing the depth of the feathers almost impossible to calculate. Once the cutting process begins the heat implemented will allow clearer visibility of the feather.

I am attaching two images showing a before and after polishing visual of the feather to better explain...

There are some technologies which allow a more accurate mapping of some inclusions within a Diamond but according to our experience those fine single-plain feathers have the ability to fool those as well...., I believe this is in regards to what Sergey wrote which i just noticed.

kenny|1407779444|3730290 said:Thanks Serg and Yoram.

Fascinating!

I'm sure I'm not the only one here on PS who appreciates learning this insider diamond knowledge.

Dancing Fire|1407822972|3730708 said:Yoram...thanks for the update..... any durability issue with the feather location?

Thanks Yoram, looking forward for more pics..DiaGem|1407852736|3730844 said:Dancing Fire|1407822972|3730708 said:Yoram...thanks for the update..... any durability issue with the feather location?

HI DF.

You will receive a full analysis on the Diamond from GOG when completed but if you are concerned, then no, this feather, its size, position & location will not cause any durability issues whatsoever.

DiaGem|1408659173|3737113 said:Interesting situation occurred which I would suspect is a rare occasion in any cutting process and which we encounter broadly.

YoramDiaGem|1408659173|3737113 said:Interesting situation occurred which I would suspect is a rare occasion in any cutting process and which we encounter broadly.

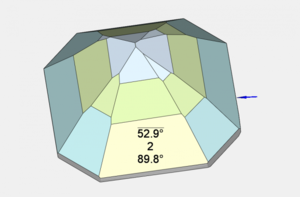

This is one recent scan of the Octavia in its present form:

P1 main is at 52.8 degrees(52.9 is erred), all other 3 P1's are at 52.4, their final planned position, angles & azimuths.

P1 52.8 is positioned smack on the rough crystal natural plane making it impossible to Polish to a shallower angle and it's impossible to polish to ideal polish. As remedy, a decision was made to polish a slight tilt from the table which will allow us to position said P1 at a 52.4 degree to match the other three P1's. It's an extremely fine-tuning gesture and a polish process so sensitive most cutters would not even consider. Needles to say the rest of the facets will have to be re-tuned to match the tilt.

This situation is being recorded for the process article. It's extremely interesting and will clearly show innovative cutting practices and the the importance to achieve top polish & 3D symmetry precision.

Dancing Fire|1408661416|3737144 said:Yoram

With these adjustments will the stone still receive AGS Ideal 0 grade? any guess of its final weight?

DiaGem|1408659173|3737113 said:Interesting situation occurred which I would suspect is a rare occasion in any cutting process and which we encounter broadly.

This is one recent scan of the Octavia in its present form:

P1 main is at 52.8 degrees(52.9 is erred), all other 3 P1's are at 52.4, their final planned position, angles & azimuths.

P1 52.8 is positioned smack on the rough crystal natural plane making it impossible to Polish to a shallower angle and it's impossible to polish to ideal polish. As remedy, a decision was made to polish a slight tilt from the table which will allow us to position said P1 at a 52.4 degree to match the other three P1's. It's an extremely fine-tuning gesture and a polish process so sensitive most cutters would not even consider. Needles to say the rest of the facets will have to be re-tuned to match the tilt.

This situation is being recorded for the process article. It's extremely interesting and will clearly show innovative cutting practices and the the importance to achieve top polish & 3D symmetry precision.

Serg|1408692425|3737357 said:DiaGem|1408659173|3737113 said:Interesting situation occurred which I would suspect is a rare occasion in any cutting process and which we encounter broadly.

This is one recent scan of the Octavia in its present form:

P1 main is at 52.8 degrees(52.9 is erred), all other 3 P1's are at 52.4, their final planned position, angles & azimuths.

P1 52.8 is positioned smack on the rough crystal natural plane making it impossible to Polish to a shallower angle and it's impossible to polish to ideal polish. As remedy, a decision was made to polish a slight tilt from the table which will allow us to position said P1 at a 52.4 degree to match the other three P1's. It's an extremely fine-tuning gesture and a polish process so sensitive most cutters would not even consider. Needles to say the rest of the facets will have to be re-tuned to match the tilt.

This situation is being recorded for the process article. It's extremely interesting and will clearly show innovative cutting practices and the the importance to achieve top polish & 3D symmetry precision.

Yoram, please publish photo from same direction. I want compare edge junctions from model with edge junctions from real diamond.

if we see significant difference then real slope angles would be different.

also I advice scan the diamond in 4 different positions ( rotate on +90 degree each time ) then compare slope angles for same facets

Yes Karl, it's a nano shifting of the position (imagine we need to slightly tilt the position of the Diamond in order to reposition the problematic P1 from 52.8 deg to 52.4 deg. (4 tenths of 1 degree when the margin of error on tech is 1.5 +/- e.g. 3 tenths of 1 deg.)Karl_K|1408690866|3737349 said:DF, I am learning much of this along with everyone else but I think what is going to happen can be simplified like this and Yoram can correct me if I understand it wrong.

Picture your diamond floating inside it.

Some of it will be left and some removed to form your diamond.

What he is doing is shifting what will be your diamond slightly, some of what would have been removed is saved and some of what would have been saved is removed.

In the end it comes out perfect to plan just slightly shifted inside the material.

The finished diamond is the same either way.

Hi Sergey,Serg|1408692425|3737357 said:DiaGem|1408659173|3737113 said:Interesting situation occurred which I would suspect is a rare occasion in any cutting process and which we encounter broadly.

This is one recent scan of the Octavia in its present form:

P1 main is at 52.8 degrees(52.9 is erred), all other 3 P1's are at 52.4, their final planned position, angles & azimuths.

P1 52.8 is positioned smack on the rough crystal natural plane making it impossible to Polish to a shallower angle and it's impossible to polish to ideal polish. As remedy, a decision was made to polish a slight tilt from the table which will allow us to position said P1 at a 52.4 degree to match the other three P1's. It's an extremely fine-tuning gesture and a polish process so sensitive most cutters would not even consider. Needles to say the rest of the facets will have to be re-tuned to match the tilt.

This situation is being recorded for the process article. It's extremely interesting and will clearly show innovative cutting practices and the the importance to achieve top polish & 3D symmetry precision.

Yoram, please publish photo from same direction. I want compare edge junctions from model with edge junctions from real diamond.

if we see significant difference then real slope angles would be different.

also I advice scan the diamond in 4 different positions ( rotate on +90 degree each time ) then compare slope angles for same facets