adamasgem

Brilliant_Rock

- Joined

- May 23, 2003

- Messages

- 1,338

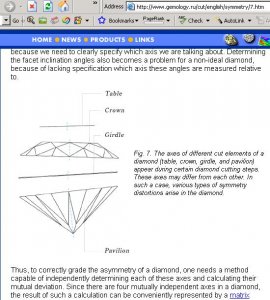

Rhino The table and the pedestal planes are supposed to be coincident, the only way what you are suggesting could happen is if there is dirt under the table, and the table doesn''t make contact.Date: 1/27/2007 4:33:07 PM

Author: Rhino

Good question. My guess would be the average of each of those planes.

Here''s a question for ya Serg. If the Helium is using the table plane as its reference and the table is tilted will this skew the results of the Helium scan causing it to give faulty measurements?

Their is the subtle issue of a tilted pedestal in all scanners.

300x240.png)